Solution

Supported by the global influence of the Department of Chemistry of the College of Chemistry and Chemical Engineering, Xiamen University in catalytic technology research, Amoycat has integrated software and hardware strengths in talent team, high-end instrument and fundamental theory of the State Key Laboratory of Physical Chemistry of Solid Surfaces, the National & Local Joint Engineering Research Center of Preparation Technology of Nanomaterials and the Tan Kah Kee Innovation Laboratory. We have conducted in-depth strategic cooperation with central enterprises or listed companies such as Sinoche and Sinopec to establish sustainable innovation capacity in breakthrough ranging from fundamental research principle to applied research technology. Moreover, we have built full chain service level ranging from small test development to pilot plant test verification and industrial production and can offer clients both at home abroad integrated solutions of small test, pilot plant test and mass production technology packages for green hydrogen catalysis technology, including catalyst structure design, property evaluation, application guide, failure analysis, recycling, safety risk assessment, pilot plant test service, technology package development, etc.

Fine chemicals industry

Targeted at fine chemicals, Amoycat has focused on developing green catalytic hydrogenation technologies for chemical intermediates with high value-added such as pesticides, dyes, pigments, veterinary drugs, medicines, vitamins, flavors and fragrances.

New chemical materials industry

Targeted at new chemical materials, Amoycat has focused on developing high-purity monomer green catalytic hydrogenation technologies for high-performance new materials including high-performance fibers, special engineering plastics, special rubbers, polyesters, polyurethanes and liquid crystals.

Low-carbon hydrogen energy industry

Targeted at low-carbon hydrogen energy, Amoycat has focused on developing new clean and green catalytic technologies for hydrogen fuel cells, PEM water-electrolysis hydrogen production, AEM water-electrolysis hydrogen production, hydrogen production with ammonia decomposition and organic liquid hydrogen storage.

Fine chemicals industry

Targeted at fine chemicals, Amoycat has focused on developing green catalytic hydrogenation technologies for chemical intermediates with high value-added such as pesticides, dyes, pigments, veterinary drugs, medicines, vitamins, flavors and fragrances.

New chemical materials industry

Targeted at new chemical materials, Amoycat has focused on developing high-purity monomer green catalytic hydrogenation technologies for high-performance new materials including high-performance fibers, special engineering plastics, special rubbers, polyesters, polyurethanes and liquid crystals.

Low-carbon hydrogen energy industry

Targeted at low-carbon hydrogen energy, Amoycat has focused on developing new clean and green catalytic technologies for hydrogen fuel cells, PEM water-electrolysis hydrogen production, AEM water-electrolysis hydrogen production, hydrogen production with ammonia decomposition and organic liquid hydrogen storage.

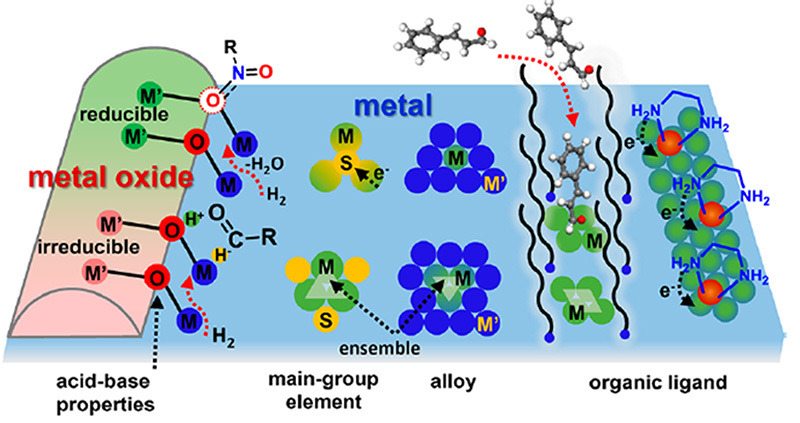

Catalyst structure design

Amoycat comprehends nanocatalyst micro-structure and understands reaction mechanism at sub-nanometer scale so as to precisely design catalyst structure, regulate and control properties of nanocatalysts and realize practical application of high-selectivity nanocatalysis technology.

Amoycat has conducted theoretical calculation and simulation research on density functional theory and molecular dynamics based on model catalyst and model reaction design, to deepen our understanding of catalytic mechanism and guide catalyst design.

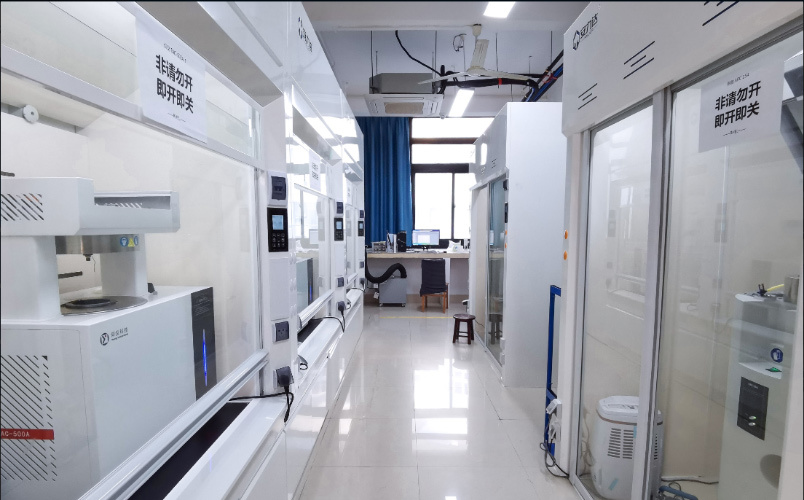

Catalyst property evaluation

Catalyst property depends on not only variety and content of metallic elements in the catalyst but also metallic particle size and acting force between metal and carrier as well as operating conditions in real reaction system.

Amoycat offers clients multiple catalyst evaluation systems for intermittent kettle reaction, continuous kettle reaction, continuous slurry-state reaction, dynamic continuous tube reaction, continuous fixed bed reaction, etc. so that our clients can select optimal evaluation system and optimal reaction technology according to catalyst and material characteristics.

Catalyst application guide

One and the same catalyst might generate entirely different catalytic reaction effects on different reactors and by different operators under same operating conditions, which consequently greatly influences product quality and yield.

Amoycat provides systematic training courses to our clients’ managers and front-line production operators to help them get familiar with the application instructions of each catalyst and give full play to each catalyst.

Catalyst failure analysis

Catalyst deactivation is one of the most common and the most nerve-wracking problems in production, which is caused by many different reasons. Understanding these reasons for catalyst deactivation can help our clients to improve service life of catalysts and reduce costs.

Amoycat offers our clients full-process services of catalyst failure analysis to help them effectively evaluate catalyst failure mechanism and carry out technological upgrading by high-end characterization means including high-resolution electron microscope technology and in-situ characterization technology.

Catalyst recycling

Catalyst recycling is also an important link in catalyst application. How to simplify recycling procedures, shorten recycling process and improve recycling rate of noble metals is crucial to production efficiency and cost.

Amoycat offers clients recycling and reprocessing of noble metal materials in waste catalysts to reduce cash flow and guarantee batch stability of products.

Reaction safety risk assessment

The main safety risks in fine chemical reaction are sourced from process thermal risk. In an exothermic reaction particularly, the higher heat release of the reaction, the higher adiabatic temperature rise. Safety risk assessment is crucial to reaction technology.

As one of first-batch nationally recognized service institutions conducting fine chemical reaction risk assessment, Amoycat offers clients fine chemical reaction risk assessment, issues high-quality reaction risk assessment reports, lowers process hazard level and clearly defines emergency response plans for thermal runaway circumstances so as to fundamentally address safety risks of fine chemical products.

Pilot plant test service for continuous hydrogenation

Continuous reaction represents an important trend of promoting safe, intelligent, high-end and green industrial production, which is a key force driving cost reduction, quality improvement and energy consumption reduction of fine chemicals and new materials with high value-added.

Amoycat has been committed to the development of continuous hydrogenation reaction technology for a long time. It offers clients integrated solutions of multiple continuous hydrogenation technologies including continuous fixed bed reaction, continuous micro-channel reaction, continuous tube-type reaction and continuous point-electric chemical reaction to boost the rapid application of new technologies and new processes in industrial production.

Technology package development

As the core of chemical industry production, technology package mainly addresses the issue of technology source and constitutes the foundation of engineering design, which plays a pivotal role in the process of chemical industry production. Anyone who has the technology package grasps all core technologies of the product.

Amoycat offers our clients integrated solutions of catalysts, reaction technologies and equipment with catalysts as the core based on integration innovation of new technologies and new equipment.

Contact us

Website: www.amoycat.cn

Address: No. 66 Xinyuan South Road, Haicang District, Xiamen City, Fujian Province, China

Official account QR code