High-selectivity Catalysts

To improve selectivity of catalysts is the fundamental means to reduce side reactions at the source and realize the goals of cost reduction and quality improvement. Amoycat comprehends principles of catalytic reaction at molecular level and designs catalyst nano-structure at atomic scale to offer clients unique market-competitive high-selectivity catalyst products including kettle reaction catalysts, fixed-bed reaction catalysts, fuel cell catalysts, water-electrolysis hydrogen production catalysts, etc.

Targeted at requirements in different application fields, Amoycat has developed various catalyst products such as Pt, Pd, Ru, Ni, Cu and Fe catalysts and has formed catalyst product families of different shapes and different sizes e.g. powdery, spherical and columnar catalysts with different carriers including active carbon, aluminium oxide, silicon dioxide and molecular sieve. These catalyst products have been widely applied in fine chemical engineering industry, new materials industry, fuel cell and hydrogen energy industry.

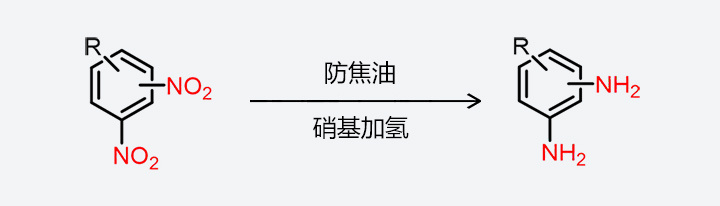

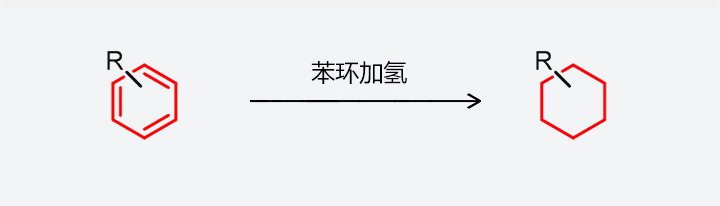

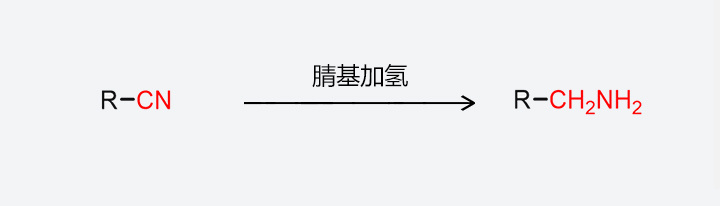

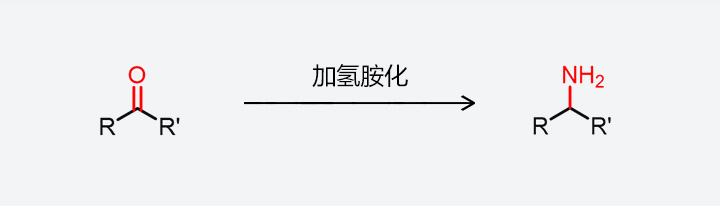

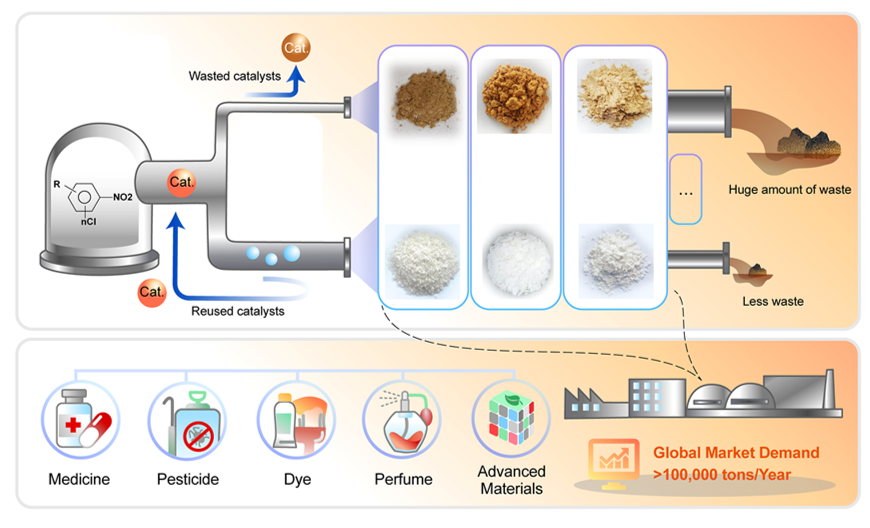

Oriented at key challenges and problems such as high pollution, high cost and poor quality in fine chemicals industries (pesticides, medicines, veterinary drugs, vitamins, dyes and pigments, etc.) and new chemical materials industries (high-performance fibers, degradable plastics, polyesters and polyurethanes, lithium battery additives, etc.), Amoycat has originally proposed the concept of non-contact hydrogenation and has developed original core catalytic technology systems including nitryl hydrogenation (tar-proof, anti-dechlorination, sulfur poisoning-resistant and customized hydroxylamine), nitrile group hydrogenation, hydrogenation amination as well as alkyne semi-hydrogenation, benzene ring hydrogenation and hydrodechlorination. Our relevant catalyst products and technology processes have been operated at central enterprises and listed companies in a steady way in Jiangsu, Gansu, Shandong and other regions, realizing 10,000-ton level industrial application of multiple products.

Facing bottleneck problems in full industry chain ranging from green hydrogen preparation to hydrogen storage, transportation and application in the field of catalytic technology, Amoycat originally invented domain-limited carrier synthesis technology which can satisfy kilogram-level manufacturing of platinum-carbon catalysts featuring high load capacity, high activity, ultra-small size and clean surface and is applicable to hydrogen fuel cells, PEM water-electrolysis hydrogen generation, AEM water-electrolysis hydrogen generation and hydrogen generation with ammonia decomposition. Our relevant catalyst products and technology processes have been verified in a high-efficiency and steady way on the devices of leading enterprises.

Nano-catalyst

Single-atom catalyst

Nano-alloy catalyst

Classical Products

Platinum-based catalysts

Palladium-based catalysts

Ruthenium-based catalysts

Nickel-based catalysts

Copper-based catalysts

Dedicated products

Fuel cell catalysts

Water-electrolysis hydrogen making catalysts

Catalysts for hydrogen generation with ammonia decomposition

Maleic anhydride hydrogenation catalysts

Applicable reactions

Selective nitryl hydrogenation

Selective benzene ring hydrogenation

Selective hydrodechlorination

Selective nitrile group hydrogenation

Selective hydroamination

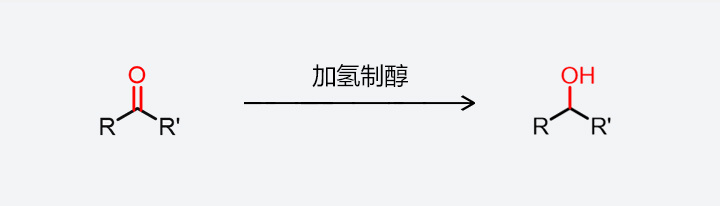

Selective aldehyde ketone hydrogenation

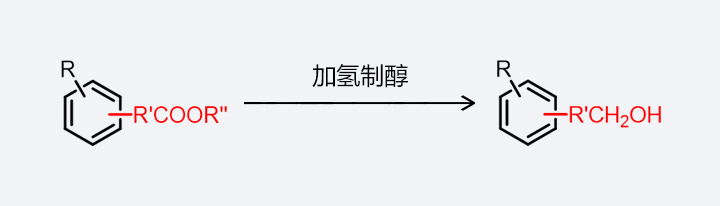

Selective ester group hydrogenation

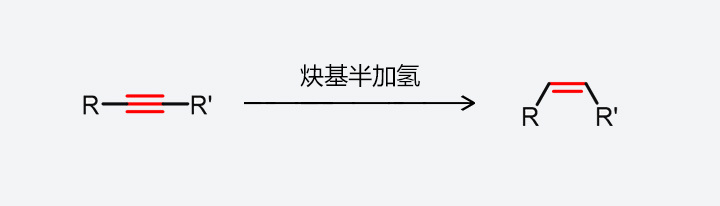

Selective alkynyl semi-hydrogenation

Product advantages

Amoycat has developed core catalytic technologies of non-contact hydrogenation by structuring catalytic systems and understanding catalytic mechanism at atomic scale to substantially improve selectivity and service life of catalysis and continuously reduce catalyst dosage. We have improved technology roadmap to avoid waste gas, waster water and solid waste and achieved unprecedented new properties. Our products boast competitive advantages including high selectivity, low cost, high quality, low energy consumption, greenness and low carbon.

Advantages in environmental protection

Amoycat has improved reaction selectivity and innovated traditional technologies at the source to substantially reduce production of waste gas, waste water and solid waste and realize near zero emission.

Advantages in cost

Amoycat has kept reducing catalyst dosage and improving process route in a sustainable way to streamline technological process and improve yield rate.

Advantages in quality

Amoycat has broken long-standing monopolies and overcome bottleneck technological problems to realize independent and controllable manufacturing of high-end products wit high value-added.

3-methyl-2-aminobenzoic acid

The Company

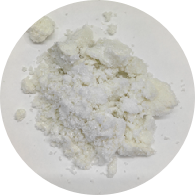

The product of our company’s catalysts (primary crystallization crude product)

Competition

Product produced by catalyst (primary crystallization crude product)

5-aminoisophthalic acid

The Company

The product of our company’s catalysts (primary crystallization crude product)

Competition

Product produced by catalyst (primary crystallization crude product)

p-phenylenediamine

The Company

The product of our company’s catalysts (primary crystallization crude product)

Competition

The product of competitors’ catalysts (primary crystallization crude product)

(ODA)4,4’-diaminodiphenyl ether (ODA)

The Company

(ODA)4,4’-diaminodiphenyl ether (ODA)

Competition

The product of competitors’ catalysts (primary crystallization crude product)

m-nitroaniline

The Company

The product of our company’s catalysts (primary crystallization crude product)

Competition

The product of competitors’ catalysts (primary crystallization crude product)

P-chloropheyl hydrazine

The Company

The product of our company’s catalysts (primary crystallization crude product)

Competition

The product of competitors’ catalysts (primary crystallization crude product)

Industry cases

10,000-ton level industrialization case of high-selectivity continuous hydrogenation catalyst

Amoycat has achieved breakthroughs in key bottleneck problems in synthesis of super-high purity monomer for new materials such as para aramid, polyesterimide, special nylon and biodegradable plastics. Our continuous hydrogenation catalytic technologies have been applied to realize 10,000-ton level industrialization at central enterprises and listed companies, helping our clients to generate new revenues amounting billions of RMB yuan. Our relevant continuous hydrogenation technologies are identified as international leading technologies and are included in the Catalogue of First-batch Technology Products to Be Encouraged, Promoted and Applied in Petrochemical and Chemical Industry Listed by the National Ministry of Industry and Information (2021), the Science and Technology Guide Plan of the China Petroleum and Chemical Industry Federation (2023) and the Directory of Green and Low-carbon Petrochemical Technologies (Version 2024).

Megawatt-level industrialization case of high-performance and low-cost catalyst for water-electrolysis hydrogen generation

Amoycat has overcome a problem in amplified production of catalyst for PEM water-electrolysis hydrogen generation to satisfy single-batch kilogram-level manufacturing of platinum-carbon nano-catalysts featuring high load capacity, high activity, ultra-small size and clean surface, which are applicable to hydrogen fuel cells, PEM water-electrolysis hydrogen generation and AEM water-electrolysis hydrogen generation. Our relevant catalyst products and technologies have been verified in a high-efficiency and steady way on the devices of our client enterprises.

Contact us

Website: www.amoycat.cn

Address: No. 66 Xinyuan South Road, Haicang District, Xiamen City, Fujian Province, China

Official account QR code